Let's Ruminate: From goating to wining!

by Josh Crise, Monthly Goat Rancher Columnist

It’s been a busy past few months. Actually, it seems it has been non-stop for the last nine months, maybe even a bit more. It started early last summer. We embarked on several new adventures last summer, one of which has turned into our latest venture to keep the homestead out of the red and operating square in the black. Goating is work. Everyone knows that. And if you don’t, I am telling you now! It is work. And sometimes no matter how hard you work, there are still obstacles along the roadway that challenge you. You either overcome those barriers or be mired in muck! Literally and figuratively.

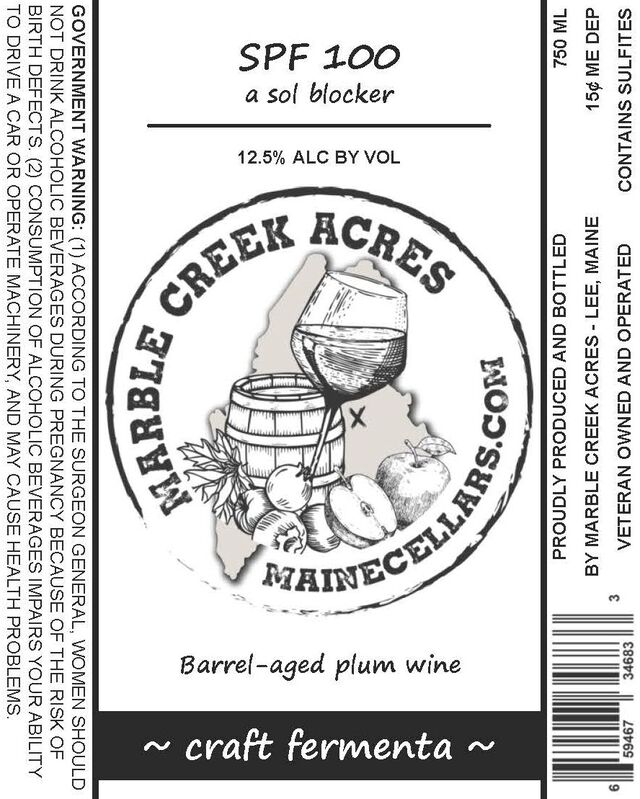

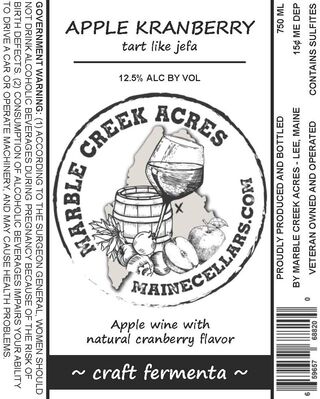

We are always looking for the next angle around here to turn a buck. Not a Kiko sire but you know the green stuff that pays the bills. As I shared in a previous article, our latest venture is opening a winery and onsite tasting room. This past week we crossed the proverbial finish line. Actually, it is more like crossing the starting line. Everything leading up to this point was all workout sessions getting us ready for the big day. In any case, we sold our very first bottle of wine! Maybe a little corny, but my mother bought the first bottle, “APPLE KRANBERRY tart like jefa”, which is one of Kathy’s favorites. Within the week, we sold our first 100 bottles. A great start!

Not taken lightly, but our decision to open a winery also came out of a desire to add an offering to our community that might draw more vacationers to the area, including campers, RVs, etc. but also provide a new place for locals to enjoy a glass or flight of wine in town. Initially, I just wanted to be able to legally sell craft wine to campers/RVers who stay with us during RV season. The short of it is, that idea morphed into a wine production area with an integrated commercial kitchen. Maybe a bit more than we absolutely needed but now I can serve food in the future if we desire. Likely never a full restaurant but I would like to be able to serve a meal of the day.

Let’s back up just a bit. You might be saying to yourself, how do you get from goating to wining!? And better yet, how do you acquire those skills? I liken the process of making wine to two specific skills. More on this in a bit. Still, isn’t it a leap? In my head, no. All in, yes! There is no in between for me. If you are going to do it right, you have to be all in. Growing up, my mom and dad instilled a number of values in me. Maybe the most important, whether they explicitly said it was the sky's the limit. I have heard it this way too … Think big! Think the world big! I say go big or go home. My parents explicitly used to say when I was growing up, “you can do anything you put your mind to.” That particular value has always stayed with me, and to this day, I truly believe it. I may not be the best or #1 at all of the skills I have acquired over the years, but as a jack of many trades, it has opened many doors for me over the years. Thanks mom and dad!! And this new venture is no exception.

Now let’s take a look at those skills. As I noted, I liken winemaking to two specific skill sets. Both skills I acquired from my dad and continued to develop as I eloquently aged. Okay, okay, maybe not eloquently!! Definitely aged. Just remember, fine wine is aged, so I must be like fine wine. I digress. Moving on!! One of the skills came from my dad’s near lifelong background in the swimming pool industry. Among other roles throughout the years, for about 10 years, my dad owned his own swimming pool route. And as a kid we had a swimming pool as well. As an adult I own a swimming pool. At this point you are probably saying what? What does this have to do with winemaking? Remember, I said two skills. The first skill is maintaining the appropriate balance of compounds in your swimming pool to keep it crystal clear and from turning green. I will come back to explain in a moment.

The second skill came out of a hobby. Growing up, my dad introduced me to reloading bullets. My dad passed this skill on to me after having it passed on to him by his older brother, my Uncle Teeny (Grover, III). They used to trek out on various camping trips, sometimes reloading, with handloaders, specifically .30-40 krag, while other times they would use their single-stage press sitting in the garage to make various rounds for whatever caliber they were shooting or plinking with at the time. Both of these skills, swimming pool maintenance and reloading, require attention to detail. Some might call this skill by another name. I just think of it as being process oriented which is a requirement to make quality wine.

So, let’s break those two skill sets down and how they apply to winemaking. Swimming pools require a keen sense of how various compounds are used to maintain the proper balance to assure crystal clear water. It includes compounds for raising and lowering the pH, boosting the alkalinity, maintaining the calcium to prevent rusting of metal objects in the pool, like ladders, stabilizing agents to prevent chlorine from burning off prematurely, and chlorine. Chlorine is used to kill bacteria like salmonella and E. coli and germs that cause viruses such as diarrhea and swimmer’s ear. Each of these compounds work in conjunction with one another. If one of the compounds is not balanced quite right, then the others will not work efficiently, and maybe even against one another. There are also compounds used to help drop out suspended molecules in the water. Sometimes these molecules are metal, like copper. In other cases the molecules might be suspended biomatter, that the filter is unable to capture and process out of the pool.

Believe it or not, some of the compounds used above are similar to the compounds used in winemaking. They are food grade versions but nonetheless have similar effects. And like maintaining swimming pools, each is used at specific times to balance the wine. If the wine is not properly balanced then it will not have the proper mouthfeel, might seem overly tart, or acidic, permit bacteria to grow, or oxidize the wine causing it to turn to vinegar.

The process of making wine is fairly straightforward. Identify the wine type you wish to make. Whether from whole fruit, juice or concentrate, as an example. The sugars in the fruit are fermentable, which allows yeast to convert the sugar in the fruit to alcohol. Wine can be made from other blends as well, including maple syrup, honey, sugar water, etc. It just needs to have sugar. Then various compounds are added to produce a well balanced, and stable wine.

For example, you check the pH and raise it or lower it to approximately 3.0-3.5. This ensures that the wine is protected during the process so that bacteria is less likely to grow and makes the rest of the compounds you're using more effective. pH is raised using Sodium Bicarbonate. Raising the pH is not done often, only typically with citrus fruits. To lower pH, which is done more often, you use acid blends, or individual acids, like citric, malic, or tartaric acids to hit the sweet spot. Food grade Urea (yeast nutrient) is added to ensure that yeast has enough available nutrients to efficiently convert sugar to alcohol. Sodium or potassium metabisulfite is added to stabilize and protect the wine from oxidation, bacteria, and germs. It has similar effects to chlorine in a swimming pool. You can also add tannin, to increase mouthfeel, if needed, and pectic enzyme which helps to break down fruit compounds, extract sugar, and binds with molecules so they will settle out during the aging process.

From time to time, swimming pools require a compound called Drop Out to assist with binding to particles so they will drop out helping the water to become crystal clear. In wine, Sparkolloid, or something similar, is used to do the exact same thing. Finally, with winemaking you rack, or move your wine from one vessel to another, to get it off of the lees or must. This is the muck that has settled out at the bottom of the tank, or carboy. In a swimming pool, you do not rack the liquid to a new container but rather you vacuum, either using an automated shark or you do it manually, the muck or crud to the filter, or you drain it off. Very similar but slightly different approaches to accomplish the same thing. Clearing the water or wine to produce a crystal clear and polished looking liquid. I have highlighted some of the basic steps which are very similar to maintaining a swimming pool. This is the first few steps in winemaking. Mix it up, rack it to get it off the muck after initial fermentation, then let it age, and complete secondary fermentation.

Eventually though, it is ready to be bottled. This is where the similarities to reloading become evident. The basics of reloading, include first doing your research and formulating and documenting your intended round by reviewing reloading data. Then you get down to the actual work, starting with empty cartridges, or brass, which require the primer to be knocked out or decapped. Then you clean the primer pocket, tumble the brass to make it shiny and get the debris off of it, resize it by running it through a press, verify the length of the cartridge. It can’t be too long. Shorten it if needed. Debur the brass if by chance you had to shorten the case. Then you press the primer in the pocket, weigh the powder, and put it in the case, and then press the bullet into the top of the case. This is a shortened version of the process, but you get the idea.

With winemaking, obviously, there are differences but the concepts are similar. First you need to research (dream up) your formula, get your formula approved by the Alcohol and Tobacco Tax and Trade Bureau (TBB), and then get your label approved. This is actually two different entities at the TBB. The left arm and the right. Not sure they talk to each other as well as they should but the system is better than it used to be from what I have heard. Then you take a bottle (the bullet case), and you clean it and sanitize it. It’s then filled with aged wine (the gunpowder). And then pressed to insert the cork (the bullet). Each bottle is then wiped down, an approved label is applied, and then a heat shrink cap is placed on top and warmed. The end result is a bottle of your favorite wine. In my case a bottle of wine that is one step closer to producing a case of wine, and one step nearer to selling it locally in our wine tasting room or to a convenience store.

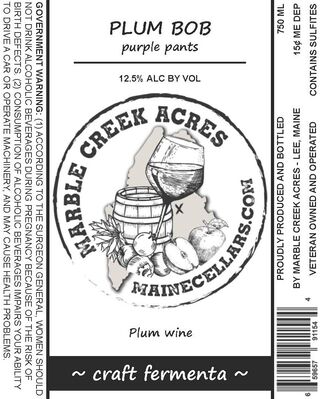

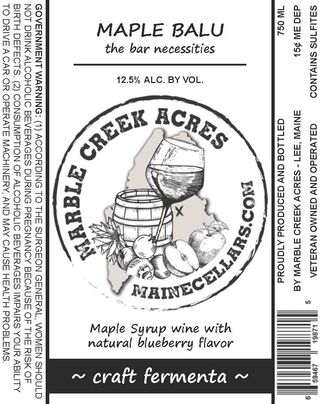

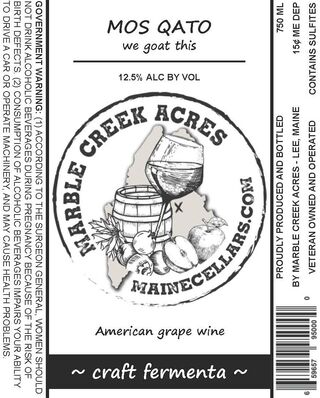

Through this entire process, you may be wondering, what on Earth does this have to do with goats? The answer to that is 2-fold. One, we are always happy to share our goating experience with anyone. We are converting our farm store into a temperature controlled tasting room/farm store. We will continue to raise goats and offer goat meat in our freezers. And continue to share our goating story with anyone that wishes to listen. Two, we are a naming crazy family. Our goats are all named, yes, we know, but they still get processed when necessary. Our naming scheme has delighted us for our entire ranching journey. The word KIKO is what inspired all of our names, every single one of the goats has a 4 letter name, with 2 syllables. Balu, Qato, Pixi, Popi, sometimes real names, other times invented words. We have already found the same joy in naming our wines, even falling on our goats to provide inspiration. For example, Balu is a beautiful blue momma that has given us 4 seasons of blue kids. Josh created a maple syrup blueberry wine. Voila! MAPLE BALU the bar necessities was named and is currently our #1 seller! Other names are just for fun, like SPF 100 a sol blocker (see label) in honor of the Total Eclipse happening the week that we are tentatively opening our tasting room!

My journey to making wine started nearly 40 years ago with the values instilled by my parents. “You can do anything you put your mind to.” My journey continued with new hobbies like reloading passed down by my dad and uncle Teeny (Grover, III). On a side note, I am sure my parents were not at all impressed, my uncle also gave me a tarantula to raise at home. And finally, my dad shared his knowledge of maintaining swimming pools early on, which provided one of my first employment opportunities as a swimming pool liner specialist, and enabled me to maintain the compounds needed to keep a crystal clear pool. Values instilled early, passed down hobbies, and shared skills provide for a new business start-up opportunity and a lifelong passion for learning. Whether you are a wine aficionado or a DIY winemaker there are likely skills you learned throughout your journey!!